Contractor: Wharton Williams (2W) Location: Fulmar Field

Client: Shell

Personal Statement: Bernard Martin Date: 11 April 2018

Statement: Bernard Martin – Photographic Technician

I was employed as a freelance Photographic Technician by Warton Williams (2W) onboard the DSV Stena Workforce. Date and year are unclear now but I think it was 1984. 2W were contracted by Shell to carry out various inspection and construction tasks on its installations in the Northern, Central and Southern areas of the North Sea.

The vessel was located at one of the corners of the Fulmar Platform. We had just launched the bell with two saturation divers onboard, for one of them it was his first sat dive. It was late evening and getting dark. I was able to witness the start of the fire. I was standing on the back deck next to the ROV shack, talking to the ROV supervisor having just loaded the bell basket with cameras. The moonpool was located mid-ships of the vessel underneath the helideck. The hot water machine that supplied the divers with hot water to their suits was located on a gantry deck just above the moonpool itself. We saw smoke and the flames come from this location, the fire very quickly escalated with the whole moonpool area engulfed in flames.

The vessel’s fire alarms sounded and divers and ship crew quickly assembled. There were problems getting water to the fire hoses. It was later estimated that it took 6 minutes for the hoses to be deployed successfully. The Fulmar Platform activated its fire monitors aiming them directly down onto us, but the helideck acted as an umbrella. A Standby, or supply vessel, moved around to our portside aft and deployed its fire monitors directly into the source of the fire. It only succeeded in knocking the fire team, who had by now deployed their own hoses, off their feet and who were in danger of being pushed directly into the fire itself. The Standby vessel was told to move off. I seem to remember both the Platform and Standby vessel continued to use their monitors in drenching mode.

At the time my own personal concern was that there were O2 and Helium gas quads stored around the moonpool that were now in the centre of the fire. There was no way of getting from the deck forward to the rest of the vessel hence to the muster point or lifeboats. We had retrieved a large boat fender from the Fulmar Platform some days before and it was chained to the back of the deck and provided some shelter from the heat. The ROV supervisor and I decided that if we had to abandon ship then we would attempt to jump overboard in an area of quiet water between the aft thruster and the main propeller and attempt to get to the platform as the vessel was still on DP alongside the platform. We helped as best we could with hauling hoses.

I have no recollection at the present time of how long it took to bring the fire under control - it seemed like many hours. Luckily there had been no failure of the gas quads.

The remainder of this statement is made up of conversations with others involved after the fire and during attempts to recover the bell.

The bell with the divers onboard had stopped at -50mts the umbilical had burned through and it was secured only by the winch wires. The divers were in survival bags and using the bells onboard gas supply and were in contact with dive control via the through water comms system.

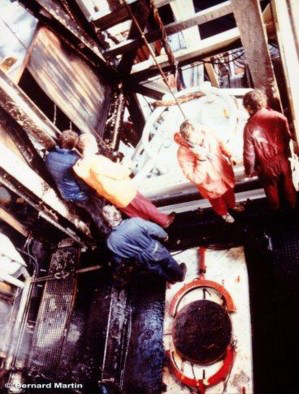

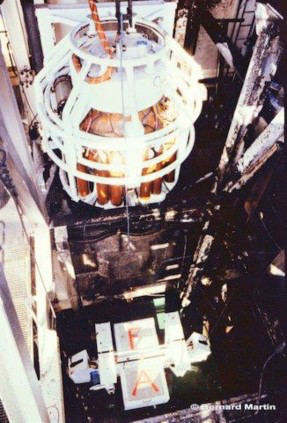

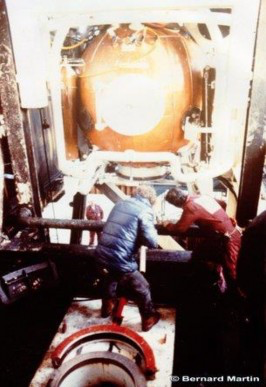

Following the assessment of damage, to the best of my recollection, the method of recovery involved an air diver attaching the vessels crane wire to support the bell winch wires in case they failed during the recovery due to heat damage. It was a slow process the heat has deformed various components.

With the bell on the surface and in the cursor, it was trollied over to be docked on to the TUP (Transfer Under Pressure). The bell was mated but the docking latches had deformed with the heat so only the weight of the bell held a seal with the TUP.

With the bell now out of the water, the through water comms inoperable in air signs were held up to the viewport of the bell, telling the divers inside not to open the bottom hatch. They apparently did not see this and opened the hatch and dropped down into the TUP and accessed the saturation chamber.

I witnessed all the above, but was told later that the dive supervisor was physically sick when they dropped out of the bell, fearing a catastrophic decompression.

During the fire and afterwards I was told that the there was considerable smoke ingress into the Saturation Control area (Sat Control) where the divers were held in Saturation. The Life Support Technicians (LST’s) wore breathing apparatus and stayed at their stations throughout. I was also told that there was a time when the divers stored inside the chamber were instructed to assume the head down feet up position as there was no access to the Hyperbaric Lifeboat.

The crane wire was attached to the bell to support the winch wires

The bell winched up into the cursor

Recovering the burned umbilical

Recovering the burned umbilical

The bell was mated but the docking latches had deformed with the heat.

So only the weight of the bell held a seal

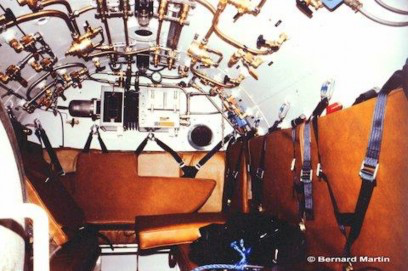

When the vessel was mobilised for the project a brand new hyperbaric lifeboat was incorporated into the vessels saturation system allowing divers stored under pressure safe evacuation in the event of an emergency. It was later established that the apparently fire-proof Tintactic foam had been painted and it was the paint igniting that caused the foam to catch fire causing the loss of the lifeboat.

Top of Hyperbaric Lifeboat

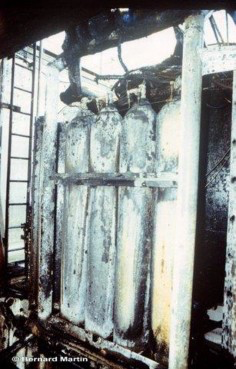

Onboard Gas Bottles

Smoke damage to the inside of the Hyperbaric Lifeboat

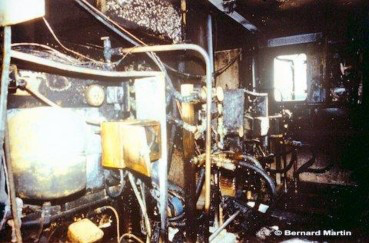

The cause of the fire was traced to the hot water machine above the moonpool area. I do not remember if it was a rubber hose that had perished causing diesel vapour to come into contact with the heating elements of the hot water machine. I seem to recall that after the fire all soft hoses were removed and replaced with hard pipework.

Drums of heat expanded diesel were also found. Recommendations also included these be stored in a separate area away from the hot water machine.

Seat of the fire. The hot water machine located above the moonpool

Incredibly there was only one injury; a stewardess injured a finger while making sandwiches for those working beyond their shifts. No hot food was available due to loss of power related to the fire. The vessel later headed for Peterhead and then on to Leith for repair.

All of the information in this statement is from memory and from conversations with those involved at the time of the fire. No notes were recorded at the time and I have had no access to official ship’s logs or subsequent HSE reports. The photographs included in this statement were taken by me, and several sets were produced onboard in my own smoke damaged darkroom for the various bodies that were due onboard in Peterhead. It obviously was a long time ago and I may have made technical errors Any errors on this statement are therefore mine alone.

Bernard Martin – 11 April 2018

Stena Workhorse Fire Report.pdf

Recommended Comments